Watch how we turn one brilliant client’s idea into a phenomenal creation, from start to finish, right here in Cleveland, Ohio.

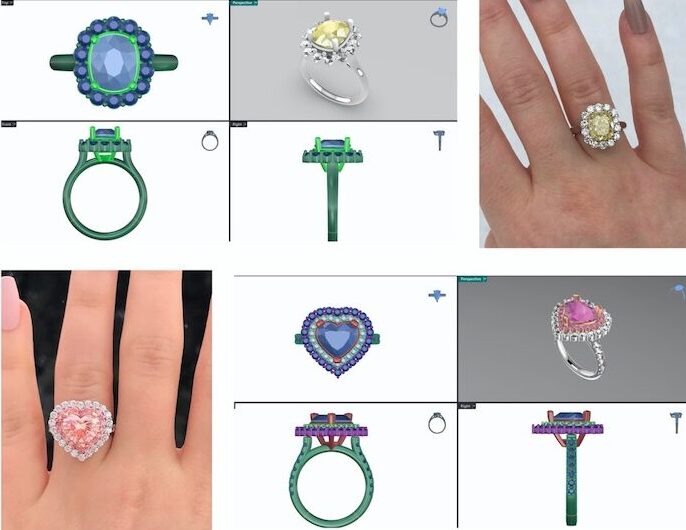

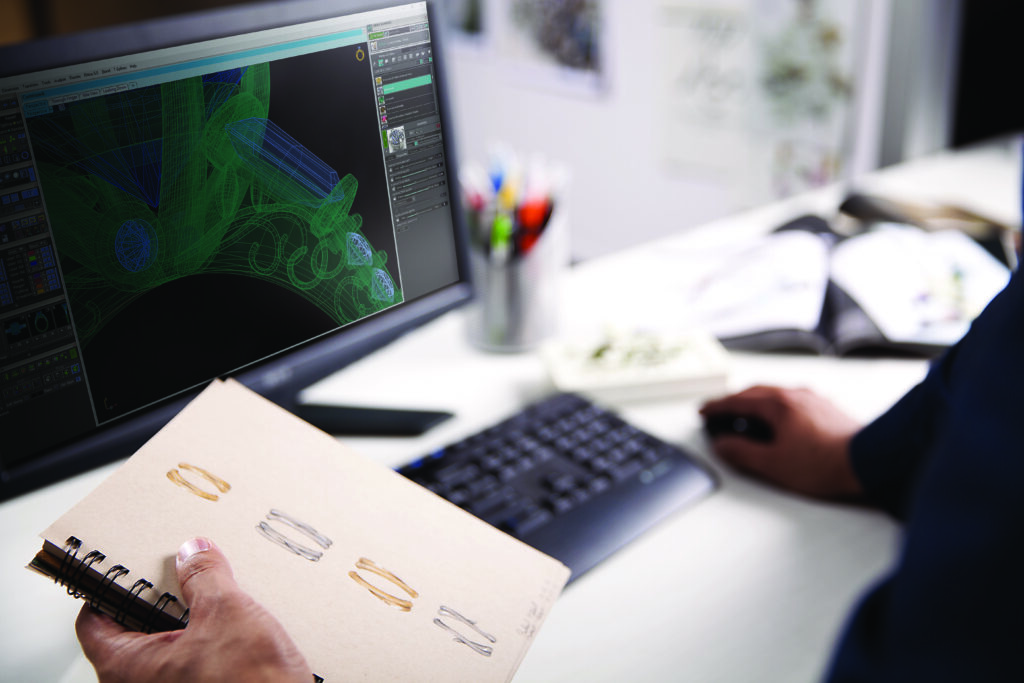

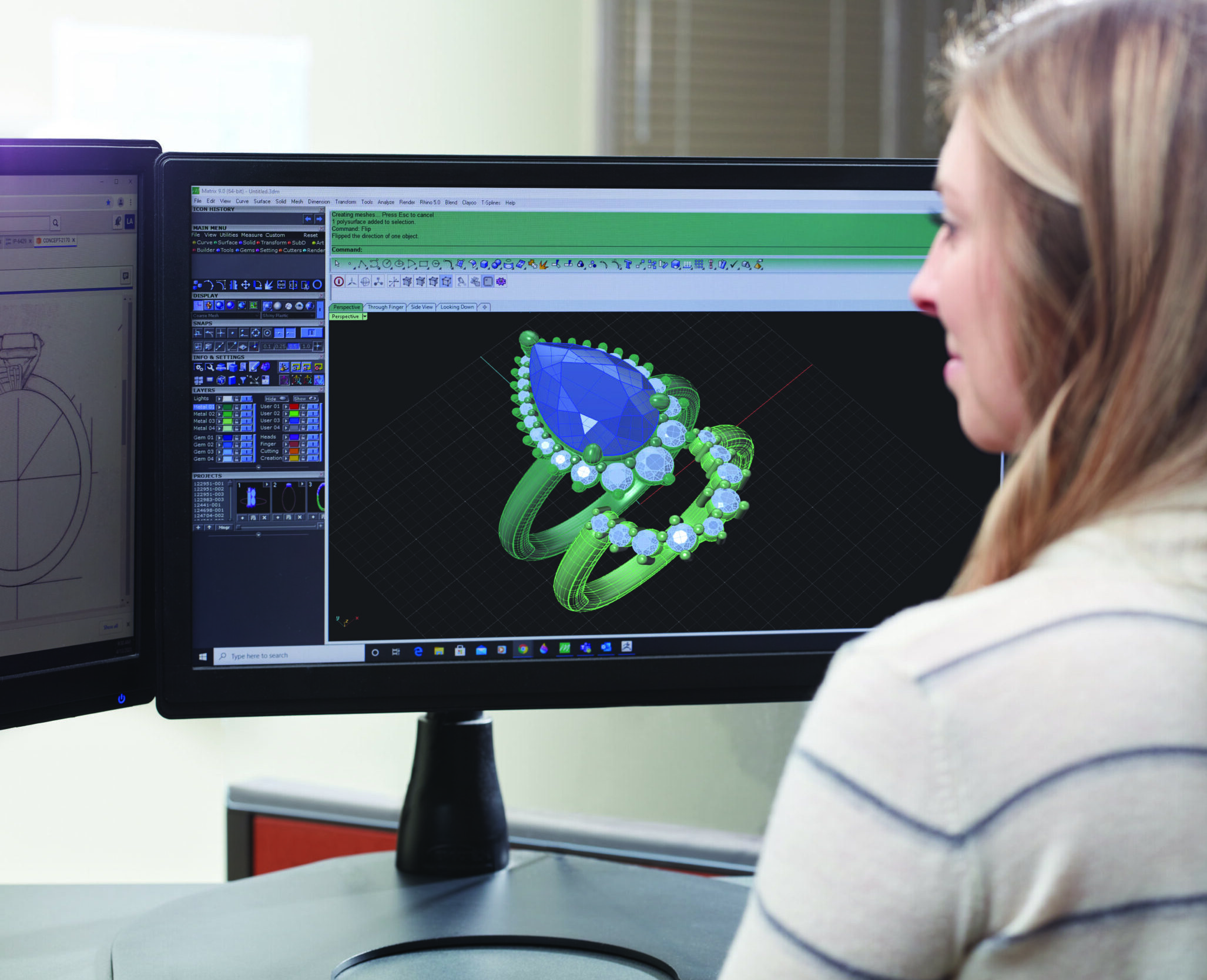

To begin, we always meet with the client to discuss their vision. We work on paper first, and then we bring the computer into the conversation. We use a very intelligent software called MatrixGold, a CAD/CAM device, to make 3-dimensional art on the computer. It can be tweaked as many times as necessary, or changed altogether. Once the piece is finished in the design process, it goes into 3-D printing.

To the take above computer image and turn it 3 dimensional, we use the B9 Creation printer. This high-tech printer can turn just about anything on the computer into a 3-D resin material, shown above on the right. Once it is cleaned, cured, and 24-hour dried, we can sprue the print onto a wax holster to anchor it during casting.

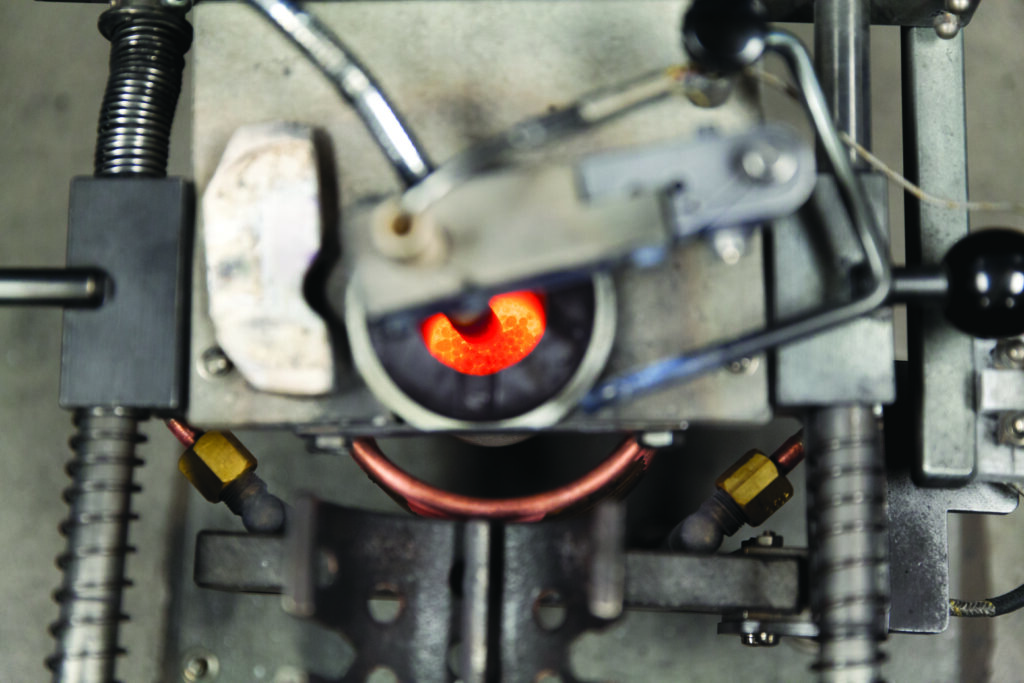

Once the resin model is “sprued” and ready for casting, we begin a process called “investing.” Investing means to mix a slurry to pour over the resin model in a flask. Once the investment hardens, the entire flask is placed inside a high-temperature oven for 12 hours to evaporate the resin model, leaving a negative impression inside the investment. This negative impression becomes the “mold” for our liquid gold to be formed into.

Once the resin is completely melted for those 12 hours, we prepare the casting machine to its proper melting, emmisivity, and power requirements. We take the flask out of the oven and place is in the centrifuge with the gold grains. Then, close the lid, let it melt, give it a spin, and let it settle. When we take the flask out of the centrifuge, we quench it with water, and allow the investment to wash away, leaving you with what you will see below.

A perfect casting of 18k white gold emerges from the investment flask. From here, we tumble the casting with stainless steel pins that travel at a high circular speed to remove excess investment and pre-polishes the piece. After that, Dave, the master jeweler, begins setting each individual diamond to create the most spectacular look.

Once the piece is cleaned, our master jeweler, Dave, begins the intricate and detailed stone-setting process. Dave has had over 50 years experience of high jewelry-making, and most recently completed an 80-hour job on just one necklace — with over 2,200 diamonds to be set by hand.

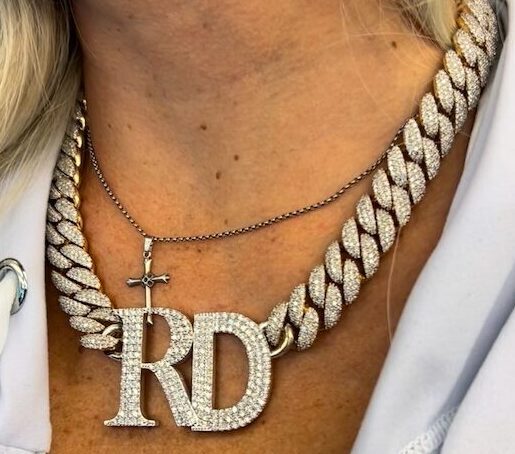

And here are just two of some finished pieces. Megan is so honored to be bringing high-quality craftsmanship and such luxury to the city of Cleveland, right here in our little neighborhood of Beachwood. Whether it’s a small piece for sentimental value, or a flashy statement piece, we are thankful for our loyal clients for shopping small, family-owned businesses.